Fabric Repairs

One of the most often requested service is Fabric Repair. With the advent of Synthetic Fabrics (Dacron) the average service life far exceeds what any of the aircraft manufacturers envisioned. This leaves a lot more time for things to happen. Sun fade, Weather or Heat checking, cracking of the finish or substrate and the one everyone hates......an accident, either major or minor. With all the above there are solutions for fixing them.

A lot of what can be done depends on the finish. Lets talk the easy ones: Dope and Polytone. These two are solvent based finishes and there are a lot of solutions for repairing. Being solvent based they can be re-top coated anytime, as long as the surface is clean and free of defects.

Dope:

One of the most asked questions centers around checking and a dulling of the top coats. There is a solution called Rejuvenator. It is a very very slow drying solvent. The process is to clean and buff the topcoat. Once this is done, the entire area to be treated is cleaned again with a good quality wax and silicone remover.

The rejuvenator is then sprayed onto the doped surface in a medium to heavy layer, but not so heavy as to run or sag. Then you wait..........and wait..... 24-48 hours.

If you have actual cracks down to the fabric this is a different beast and one you should leave to a professional.

Polytone:the standard Poly-Tone topcoat, is polyvinyl chloride, more commonly known as PVC

With Polytone there is no magic formula to soften things up. However, Polytone can be top coated any time, just like dope. The surface has to be clean and free of any cracks. If you have minor defects, these can be sanded out and filled. After all the preparation the part,area or plane can be resprayed.

Urethanes

Urethanes are a different beast altogether. These finishes include the Air-Tech process, Superflite, Aerothane, Loehle Aero Coatings.

Once these processes, and by processes I am talking about the Fabric installation and solvent cements used for the install, the base coats, which are normally a Urethane primer and then the top coats of that beautiful glossy paint.

Urethanes are catalyzed enamels. Once dry they are very durable and impervious to chemicals like acetone and MEK. They are fuel and oil resistant. But being so hard to etch, they must be mechanically abraded, to rough up the surface, should a repair be necessary. After abrading adhesive, fabric and paints will adhere. Since the paints are single stage (meaning the clear coat is in the paint) they are a bit more difficult to touch up. However, we have been doing this for a long time and have ways to hide and blend most repairs without using clear.

We advise not to use base coat clear coat systems, as most auto finishes on fabric will crack over time and the clear will yellow. Also, if a certified aircraft, you must use the STC holders process from start to finish including the topcoats as per FAA AC 43.13.1B Chapter 2.

A lot of what can be done depends on the finish. Lets talk the easy ones: Dope and Polytone. These two are solvent based finishes and there are a lot of solutions for repairing. Being solvent based they can be re-top coated anytime, as long as the surface is clean and free of defects.

Dope:

One of the most asked questions centers around checking and a dulling of the top coats. There is a solution called Rejuvenator. It is a very very slow drying solvent. The process is to clean and buff the topcoat. Once this is done, the entire area to be treated is cleaned again with a good quality wax and silicone remover.

The rejuvenator is then sprayed onto the doped surface in a medium to heavy layer, but not so heavy as to run or sag. Then you wait..........and wait..... 24-48 hours.

If you have actual cracks down to the fabric this is a different beast and one you should leave to a professional.

Polytone:the standard Poly-Tone topcoat, is polyvinyl chloride, more commonly known as PVC

With Polytone there is no magic formula to soften things up. However, Polytone can be top coated any time, just like dope. The surface has to be clean and free of any cracks. If you have minor defects, these can be sanded out and filled. After all the preparation the part,area or plane can be resprayed.

Urethanes

Urethanes are a different beast altogether. These finishes include the Air-Tech process, Superflite, Aerothane, Loehle Aero Coatings.

Once these processes, and by processes I am talking about the Fabric installation and solvent cements used for the install, the base coats, which are normally a Urethane primer and then the top coats of that beautiful glossy paint.

Urethanes are catalyzed enamels. Once dry they are very durable and impervious to chemicals like acetone and MEK. They are fuel and oil resistant. But being so hard to etch, they must be mechanically abraded, to rough up the surface, should a repair be necessary. After abrading adhesive, fabric and paints will adhere. Since the paints are single stage (meaning the clear coat is in the paint) they are a bit more difficult to touch up. However, we have been doing this for a long time and have ways to hide and blend most repairs without using clear.

We advise not to use base coat clear coat systems, as most auto finishes on fabric will crack over time and the clear will yellow. Also, if a certified aircraft, you must use the STC holders process from start to finish including the topcoats as per FAA AC 43.13.1B Chapter 2.

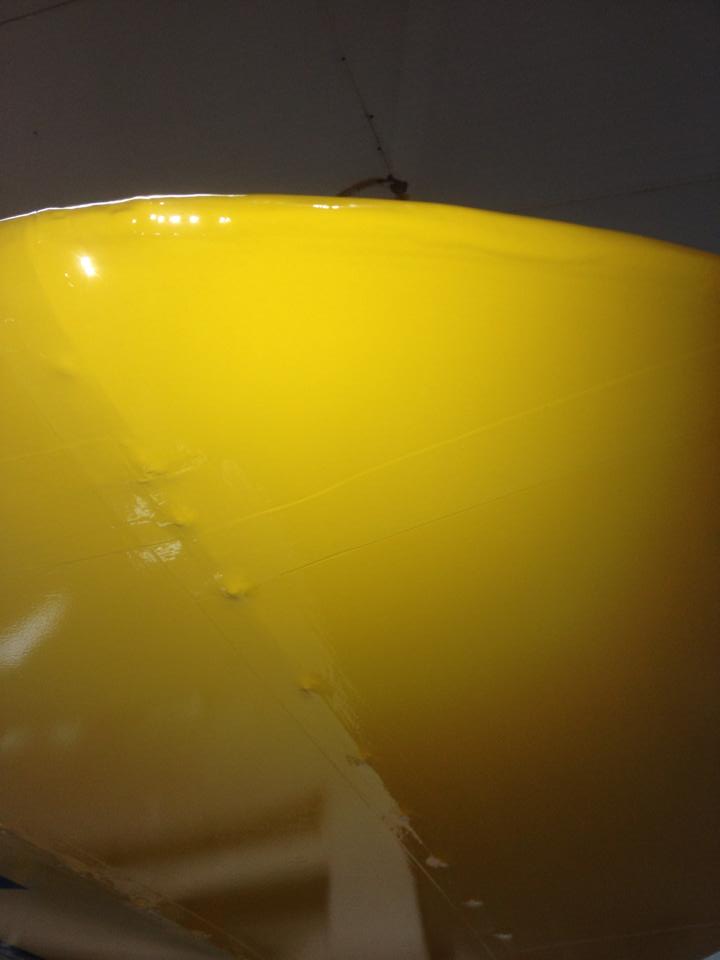

Here is a repair to a Pitts S1C that ran over a runway marker putting a divot in the aluminum, breaking the nose rib, ripping the fabric on the bottom of the wing and bottom of the horizontal stab. This was completed with the Air-Tech process in approximately 4 weeks. All rib stitching was 1" and both the knots and lacing were pulled inside the fabric. As with all my work everything including drain grommets have cloth patches. With Air-Tech you spray 3 coats of urethane primer, sanding between #2 and #3. This was a three color star burst, White goes on first, then red and finally black.

These are wing tip repairs on Aeronca Champ 7AC's that taxied into objects. It bent the tube enough to wrinkle the fabric. I have performed more of this kind of repair then any other, doing 5 in the last 2 years. Below is a a Grand Champion Piper J3-65 that had a similar experience.

The original push rod cover (left) was really beaten up. I made a new one (right) using my english wheel.

Be sure to Email, Call or Text us if you need a quotation!

Copyright © 2023 by King Aero, Inc.- All Right reserved - Email: mking@kingaeroaviation.com